- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

NHFLEX-A

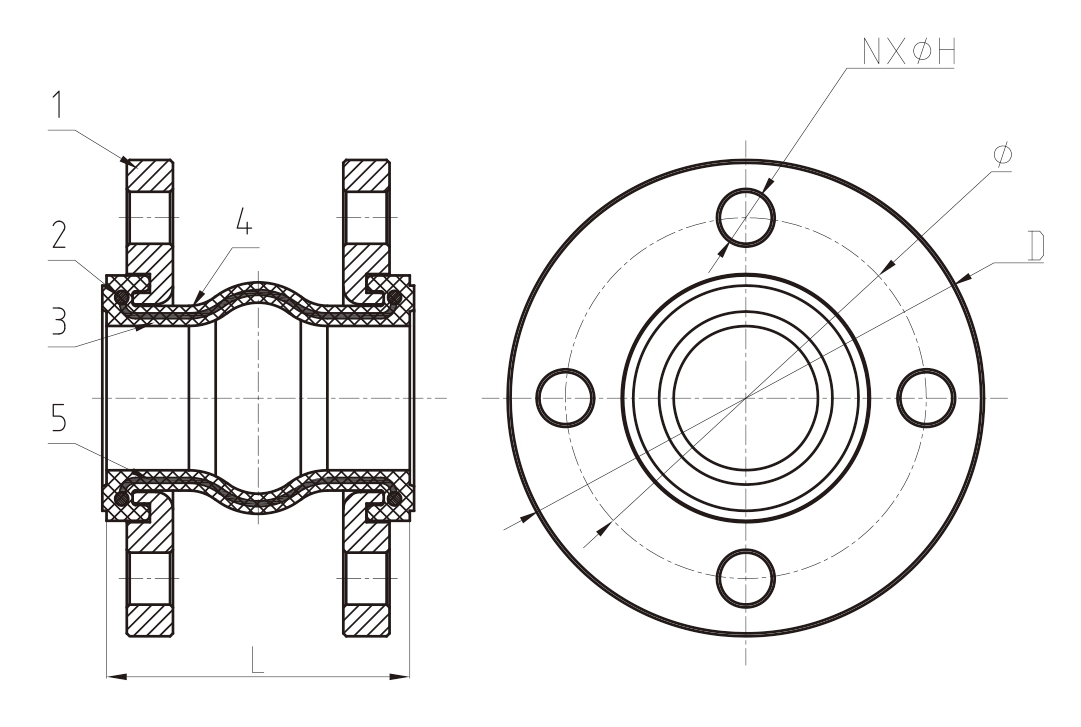

| MATERIAL SPECIFICATION | ||

| Part No. | Part | Standard Specification |

| 1 | Flange | Galvanized Carbon Steel |

| 2 | Reinforcing Ring | Carbon Steel |

| 3 | Rubber (lnner) | EPDM |

| 4 | Rubber (Outer) | EPDM |

| 5 | Reinforcing Fabric | Nylon Fabric |

NINGHAO Machinery manufactures flanged flexible rubber pipeworking expansion joints.

They allow pipe movement.

They reduce stress in pipe systems.

They maintain connection integrity.

The joint has a flange.

The flange is made of galvanized carbon steel.

A reinforcing ring is part of the joint.

It is made of carbon steel.

The joint includes two rubber layers.

The inner rubber is EPDM.

The outer rubber is EPDM.

The joint has reinforcing fabric.

It is made of nylon fabric.

This product meets standard specifications.

It suits many pipe systems.

Note: For special material request other than standard specification, please indicate clearly on the inquiry or order list.

NINGHAO Machinery's flanged flexible rubber pipeworking expansion joint offers reliable performance. It is built to standard and meets system demands. The joint provides clear connection ends, defined working pressure, a set temperature range, and fixed vacuum capacity.

Connection Ends:

The joint uses flange drilling.

It meets BS EN 1092-2:1997.

Working Pressure:

Rated at PN10/16.

It suits standard pressure systems.

Temperature Range:

Operates from 0°C to 80°C.

It fits moderate temperature applications.

Vacuum Capacity:

Maintains a capacity of 700 MM/HG.

It works in vacuum conditions.

| DN(Inch) | DN(mm) | L | D | Ø | N-ØH | Elongation | Compression | TransverseMovement | AngularDeflection |

|---|---|---|---|---|---|---|---|---|---|

| 1 1/4" | 32 | 95 | 140 | 100 | 4×18 | 6 | 10 | 10 | 25 |

| 1 1/2" | 40 | 95 | 150 | 110 | 4×18 | 6 | 10 | 10 | 25 |

| 2" | 50 | 105 | 165 | 125 | 4×18 | 6 | 10 | 10 | 25 |

| 2 1/2" | 65 | 115 | 185 | 145 | 8×18 | 8 | 15 | 12 | 25 |

| 3" | 80 | 135 | 200 | 160 | 8×18 | 8 | 15 | 12 | 25 |

| 4" | 100 | 150 | 220 | 180 | 8×18 | 12 | 20 | 16 | 15 |

| 5" | 125 | 165 | 250 | 210 | 8×18 | 12 | 20 | 16 | 15 |

| 6" | 150 | 180 | 285 | 240 | 8×22 | 12 | 20 | 16 | 15 |

| 8" | 200 | 210 | 340 | 295 | 12×22 | 12 | 20 | 16 | 15 |

| 10" | 250 | 230 | 405 | 355 | 12×26 | 14 | 30 | 25 | 8 |

| 12" | 300 | 230 | 460 | 410 | 12×26 | 14 | 30 | 25 | 8 |

| 14" | 350 | 265 | 520 | 470 | 12×26 | 14 | 30 | 25 | 8 |

| 16" | 400 | 265 | 580 | 525 | 16×30 | 14 | 30 | 25 | 8 |

| 18" | 450 | 265 | 640 | 585 | 20×30 | 14 | 30 | 25 | 8 |

| 20" | 500 | 265 | 715 | 650 | 20×33 | 14 | 30 | 25 | 8 |

| 24" | 600 | 265 | 840 | 770 | 20×36 | 14 | 30 | 25 | 8 |

NINGHAO Machinery produces flanged flexible rubber pipeworking expansion joints.

These joints serve various pipe systems.

They absorb expansion and contraction.

They reduce stress.

The joints come in sizes from 1 1/4 inch to 24 inch.

Nominal sizes appear in both inches and millimeters.

Each joint has a defined length (L) and overall diameter (D).

The nominal diameter (Ø) increases with size.

Each joint includes reinforcement rings.

The reinforcement is marked as N-ØH.

These rings add stability.

They meet size-specific requirements.

The joints allow controlled movement.

Elongation values range from 6 to 14.

Compression values range from 10 to 30.

Transverse movement reaches up to 25.

Angular deflection varies from 8 to 25 degrees.

All parameters are set to standard values.

The joints suit many working conditions.

They perform reliably under pressure and movement.

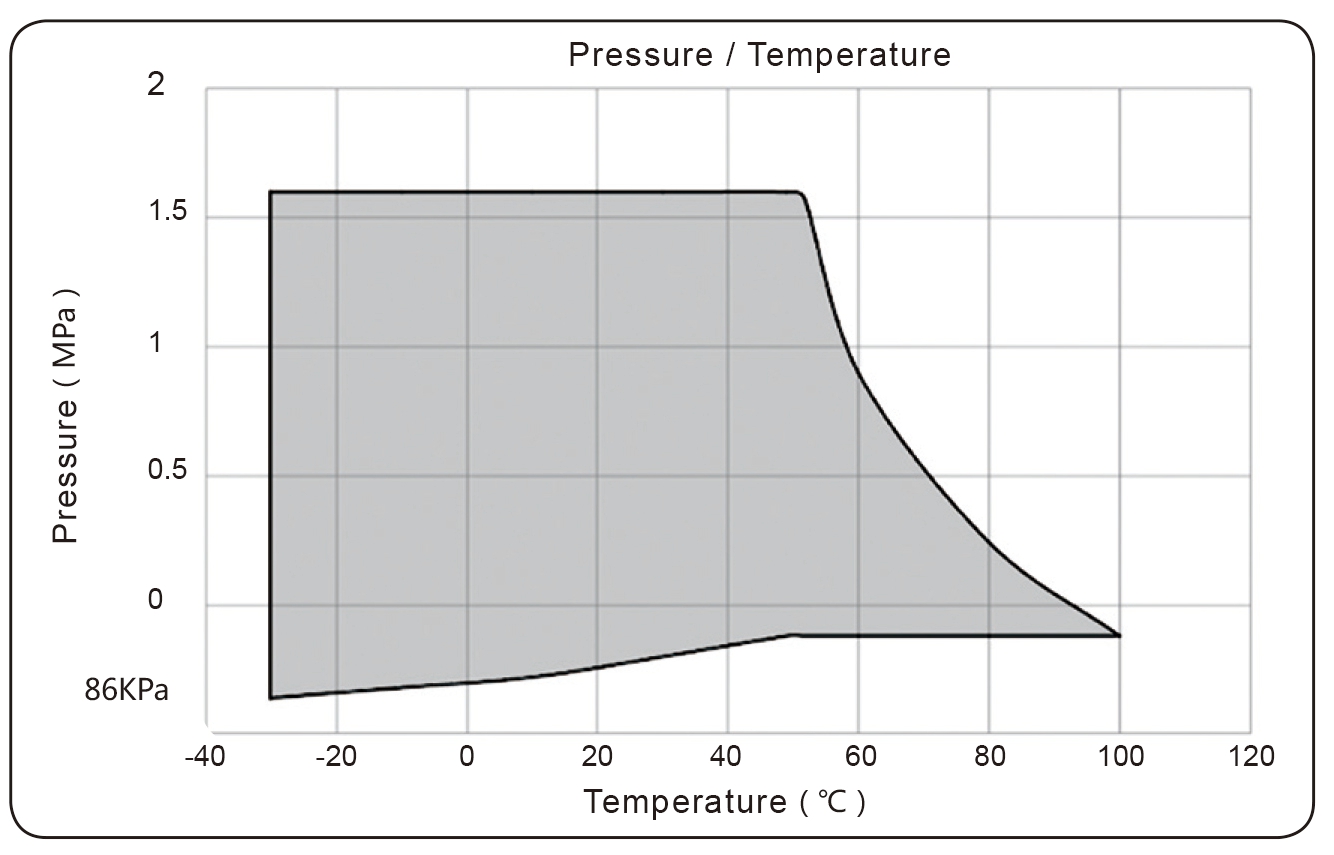

This chart shows pressure limits at various temperatures. It defines a safe working zone. The grey envelope marks allowed pressures. The guide aids design, operation, and safety checks.

Coordinate Axes (Temperature and Pressure):

The horizontal axis shows temperature from -40°C to 120°C.

The vertical axis shows pressure from near 0 MPa to about 1.5–2.0 MPa.

Grey Area (Safe Operating Range):

The grey area marks the allowed pressure range at each temperature.

Operating outside this area may introduce risk.

Phase Change or Operating Boundary:

For fluids, the grey area may follow a liquid–gas transition curve.

It shows limits for state changes or maximum safe pressure.

Exceeding these limits may cause failure.

Engineering Application and Safety Design:

Engineers use this chart for design and operational decisions.

It aids in selecting proper temperature and pressure settings.

It supports risk evaluation and equipment selection.

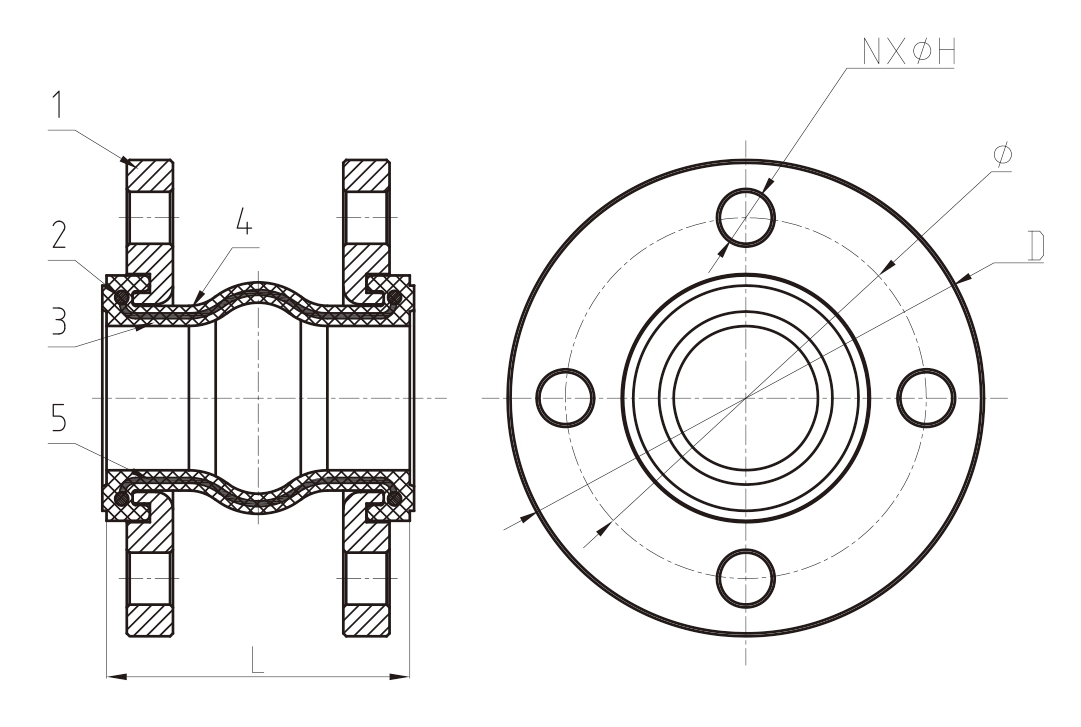

| MATERIAL SPECIFICATION | ||

| Part No. | Part | Standard Specification |

| 1 | Flange | Galvanized Carbon Steel |

| 2 | Reinforcing Ring | Carbon Steel |

| 3 | Rubber (lnner) | EPDM |

| 4 | Rubber (Outer) | EPDM |

| 5 | Reinforcing Fabric | Nylon Fabric |

NINGHAO Machinery manufactures flanged flexible rubber pipeworking expansion joints.

They allow pipe movement.

They reduce stress in pipe systems.

They maintain connection integrity.

The joint has a flange.

The flange is made of galvanized carbon steel.

A reinforcing ring is part of the joint.

It is made of carbon steel.

The joint includes two rubber layers.

The inner rubber is EPDM.

The outer rubber is EPDM.

The joint has reinforcing fabric.

It is made of nylon fabric.

This product meets standard specifications.

It suits many pipe systems.

Note: For special material request other than standard specification, please indicate clearly on the inquiry or order list.

NINGHAO Machinery's flanged flexible rubber pipeworking expansion joint offers reliable performance. It is built to standard and meets system demands. The joint provides clear connection ends, defined working pressure, a set temperature range, and fixed vacuum capacity.

Connection Ends:

The joint uses flange drilling.

It meets BS EN 1092-2:1997.

Working Pressure:

Rated at PN10/16.

It suits standard pressure systems.

Temperature Range:

Operates from 0°C to 80°C.

It fits moderate temperature applications.

Vacuum Capacity:

Maintains a capacity of 700 MM/HG.

It works in vacuum conditions.

| DN(Inch) | DN(mm) | L | D | Ø | N-ØH | Elongation | Compression | TransverseMovement | AngularDeflection |

|---|---|---|---|---|---|---|---|---|---|

| 1 1/4" | 32 | 95 | 140 | 100 | 4×18 | 6 | 10 | 10 | 25 |

| 1 1/2" | 40 | 95 | 150 | 110 | 4×18 | 6 | 10 | 10 | 25 |

| 2" | 50 | 105 | 165 | 125 | 4×18 | 6 | 10 | 10 | 25 |

| 2 1/2" | 65 | 115 | 185 | 145 | 8×18 | 8 | 15 | 12 | 25 |

| 3" | 80 | 135 | 200 | 160 | 8×18 | 8 | 15 | 12 | 25 |

| 4" | 100 | 150 | 220 | 180 | 8×18 | 12 | 20 | 16 | 15 |

| 5" | 125 | 165 | 250 | 210 | 8×18 | 12 | 20 | 16 | 15 |

| 6" | 150 | 180 | 285 | 240 | 8×22 | 12 | 20 | 16 | 15 |

| 8" | 200 | 210 | 340 | 295 | 12×22 | 12 | 20 | 16 | 15 |

| 10" | 250 | 230 | 405 | 355 | 12×26 | 14 | 30 | 25 | 8 |

| 12" | 300 | 230 | 460 | 410 | 12×26 | 14 | 30 | 25 | 8 |

| 14" | 350 | 265 | 520 | 470 | 12×26 | 14 | 30 | 25 | 8 |

| 16" | 400 | 265 | 580 | 525 | 16×30 | 14 | 30 | 25 | 8 |

| 18" | 450 | 265 | 640 | 585 | 20×30 | 14 | 30 | 25 | 8 |

| 20" | 500 | 265 | 715 | 650 | 20×33 | 14 | 30 | 25 | 8 |

| 24" | 600 | 265 | 840 | 770 | 20×36 | 14 | 30 | 25 | 8 |

NINGHAO Machinery produces flanged flexible rubber pipeworking expansion joints.

These joints serve various pipe systems.

They absorb expansion and contraction.

They reduce stress.

The joints come in sizes from 1 1/4 inch to 24 inch.

Nominal sizes appear in both inches and millimeters.

Each joint has a defined length (L) and overall diameter (D).

The nominal diameter (Ø) increases with size.

Each joint includes reinforcement rings.

The reinforcement is marked as N-ØH.

These rings add stability.

They meet size-specific requirements.

The joints allow controlled movement.

Elongation values range from 6 to 14.

Compression values range from 10 to 30.

Transverse movement reaches up to 25.

Angular deflection varies from 8 to 25 degrees.

All parameters are set to standard values.

The joints suit many working conditions.

They perform reliably under pressure and movement.

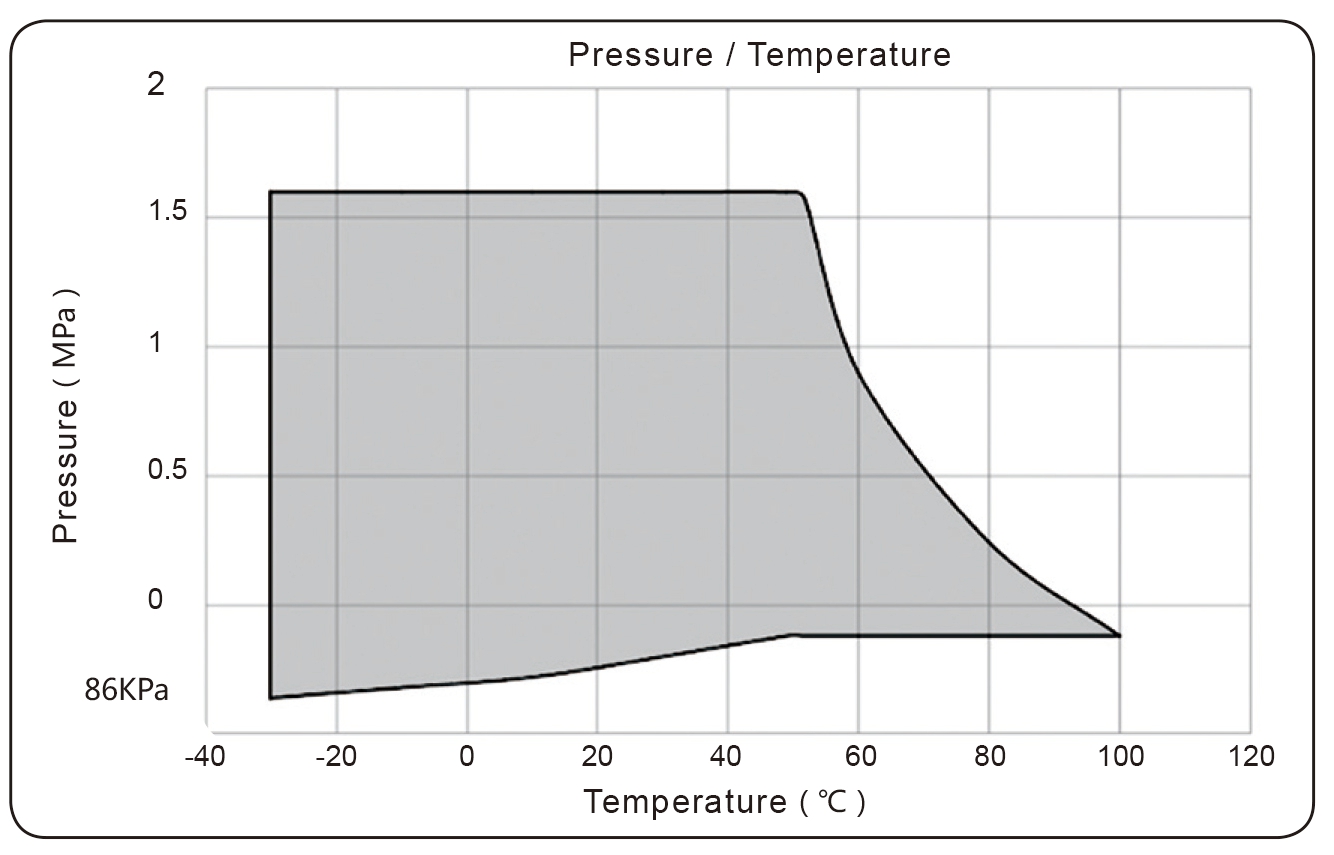

This chart shows pressure limits at various temperatures. It defines a safe working zone. The grey envelope marks allowed pressures. The guide aids design, operation, and safety checks.

Coordinate Axes (Temperature and Pressure):

The horizontal axis shows temperature from -40°C to 120°C.

The vertical axis shows pressure from near 0 MPa to about 1.5–2.0 MPa.

Grey Area (Safe Operating Range):

The grey area marks the allowed pressure range at each temperature.

Operating outside this area may introduce risk.

Phase Change or Operating Boundary:

For fluids, the grey area may follow a liquid–gas transition curve.

It shows limits for state changes or maximum safe pressure.

Exceeding these limits may cause failure.

Engineering Application and Safety Design:

Engineers use this chart for design and operational decisions.

It aids in selecting proper temperature and pressure settings.

It supports risk evaluation and equipment selection.

No.2 Taishan Road, Development Zone, Ningjin County, Shandong Province

Phone: +86-15806526381

+86-18561954252

Skype: rubberjoint1

Email: njninghaojixie@163.com